Why EEG Cable Customization Matters

Electroencephalography (EEG) plays a critical role in both clinical diagnosis and intraoperative neuro-monitoring (IONM). While much attention is given to the amplifiers or analysis software, the performance of the EEG cable itself can significantly impact signal quality, patient comfort, and operational efficiency. Standard EEG cables may not meet the specific needs of different hospital environments, patient populations, or device interfaces.

This is where customization makes a difference — by tailoring the cable structure, connectors, materials, and design details, manufacturers can deliver solutions that are truly optimized for their intended use. For example, a neurology clinic focused on pediatric epilepsy monitoring may require ultra-flexible, soft-skin cables with small connectors, while an intraoperative neuromonitoring team may prioritize robust shielding and labeled cables to ensure precision and speed in the operating room. Custom EEG cables also reduce the risk of compatibility issues, enhance durability, and help improve workflow for clinicians and technicians. In short, customization is not just about aesthetics — it’s about safety, accuracy, and clinical efficiency.

Key Customization Options

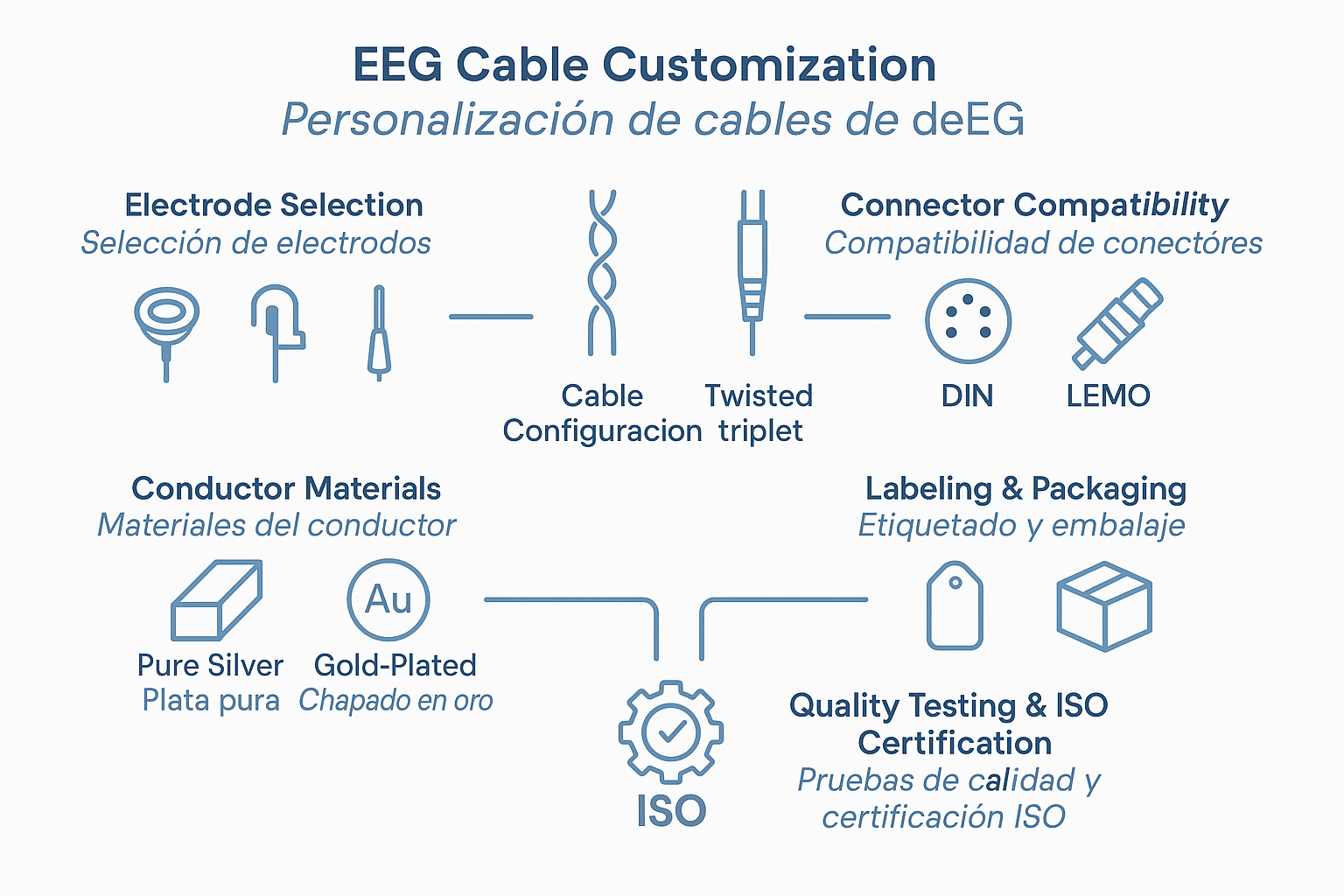

1. Electrode Type & Configuration

EEG cables can be configured with cup electrodes, earclip electrodes, subdermal needle electrodes, or disposable gel-integrated patches.

Depending on the clinical setting and local regulations, users may choose between disposable silver/silver chloride electrodes and reusable gold-plated or Ag/AgCl cup electrodes. Both have proven performance in signal quality — selection depends on hospital protocols, hygiene policies, and application scenarios (e.g. ICU, long-term EEG, IONM).

OEM Tip: Choose from multi-channel configurations: 4-, 6-, 8-, 10-, 16-, 21-, or 32-lead systems, with full flexibility.

2. Cable Construction & Twisting

Proper twisting (twisted pair/triplet) and shielding (foil or braided) reduce EMG and environmental noise, ensuring clean signal transmission.

We offer soft, biocompatible sheaths (e.g., TPU, silicone) and low-noise thermoplastic elastomers for comfort and durability.

🔍 OEM Tip: OR and IONM users often require reinforced shielding and strain-relief molded connectors.

3. Conductor Materials We provide multiple conductor types to meet clinical, safety, and performance standards: • Pure silver (99.99%) • Silver-plated copper • Gold-plated Ag/AgCl 🔍 OEM Tip: All materials are RoHS-compliant, skin-contact safe, and manufactured under ISO 13485-certified processes.

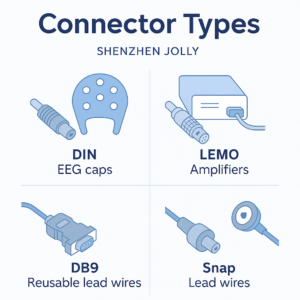

4. Connectors & Device Compatibility

We support:

1.5mm DIN safety connectors

LEMO multi-pin connectors

Standard EEG caps (6/10/12 pin)

Custom connectors based on GE, Philips, Mindray, Nihon Kohden systems

🔍 OEM Tip: Send your drawing or sample, and we can develop matching connectors with high accuracy.

4. Connectors & Device Compatibility

We support:

1.5mm DIN safety connectors

LEMO multi-pin connectors

Standard EEG caps (6/10/12 pin)

Custom connectors based on GE, Philips, Mindray, Nihon Kohden systems

🔍 OEM Tip: Send your drawing or sample, and we can develop matching connectors with high accuracy.

5. Labeling, Color Coding & Packaging Custom labels, laser-marking, and color-coded wires simplify operation.

OEM packaging options include sterile pouches, blister trays, and private label sleeves.

🔍 OEM Tip: We support packaging design and labeling services for distributors and hospitals alike.

6. Cable Length, Bundling & Cap Integration

Length can be adjusted from 80cm to 250cm

Coiled, bundled, or loose wiring available

Integration with EEG caps or headbands supported

🔍 OEM Tip: Pediatric, neonatal, and veterinary EEG systems require soft, lightweight routing — we offer fully adaptable designs.

Manufacturing & Quality Considerations

At Shenzhen Jolly, we take EEG cable production seriously — not just as a product, but as a critical interface between patient and signal system.

Manufacturing under ISO 13485 certification

Medical-grade materials, fully traceable

Thorough incoming inspection and 100% final testing

Strict verification against drawing specs

Cleanroom assembly available for selected products

We typically deliver customized EEG cable samples within 2–3 weeks after drawing confirmation, and we provide full support throughout prototype evaluation.

🌎 Export Experience We have successfully served customers from South Korea, Brazil, Europe, and North America — supporting both disposable and reusable EEG cable projects for neurology departments, OEM integrators, and IONM specialists.

📬 Ready to Customize?

If you’re seeking an OEM partner for EEG cables that combines speed, flexibility, and professionalism — we’re ready to support you.

📩 Visit: www.jyconnect.com

✉️ Or contact us directly to request a quotation or sample evaluation.